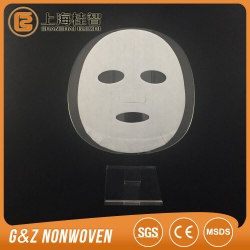

Superfine fiber Green Facial mask cloth 40g

Superfine fiber Green Facial mask cloth 40g Coconut bio Fiber Mask

Coconut bio Fiber Mask Peppermint facial mask cloth

Peppermint facial mask cloth Red wine fiber Facial mask cloth

Red wine fiber Facial mask cloth Aloe fiber Facial mask cloth

Aloe fiber Facial mask cloth olive fiber Facial mask cloth

olive fiber Facial mask cloth Imitation 60G Slines Hard

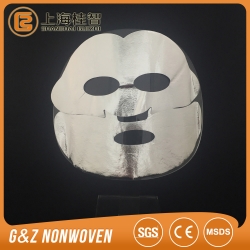

Imitation 60G Slines Hard Silvery Superconducting mask

Silvery Superconducting mask Golden Superconducting mask

Golden Superconducting mask 30%Viscose+70%Terylene Facial mask

30%Viscose+70%Terylene Facial mask Dark blue silk Facial mask cloth

Dark blue silk Facial mask cloth Charcoal Mask base cloth Dry film

Charcoal Mask base cloth Dry film Very fine fiber Yellow

Very fine fiber Yellow Water soluble cloth

Water soluble cloth Binchotan fiber Facial mask cloth

Binchotan fiber Facial mask cloth